Surfaces

In addition to the detailed design and manufacturing of the rolls, the surface quality has a huge effect on the roll. We co-operate with well-known European partners who are experts in this area. Our repertoire includes:

• Superfinish polished surfaces

• Electroplated matt or textured surfaces for extrusion coating.

• Embossing structures, etching-patterns

• Plasma-coated rolls

• Rubber-coated surfaces.

Due to our partnerships we are able to offer a complete product range in roll-technology to achieve customers’ demands or to develop new solutions for non-standard applications.

We will assist you with pleasure in choosing a suitable surface for your application.

Beside others our delivery program encloses the following surfaces:

Chrome, Finish-Polished

Roll body ground by stone, multi-layer chrome plated, ground by stone, hard chrome plated, approx. 120-130 µm final thickness ground by stone, alternatively crowned, polished and superfinish polished e.g. Rt = 0,1-0,2 µm … if required: Rt = 0,03-0,05 µm degassed

Chrome, special-designed function

Walzenballen steingeschliffen mehrschichtig hartverchromt, diRoll body ground by stone, multi-layer chrome plated, various structures like mirror-pocket, glossy-low-friction, non-blocking, a.s.o. approx. 100-120 µm final thickness e.g.. Rt = 6-9 µm, Rt = 12-15 µm a.s.o.

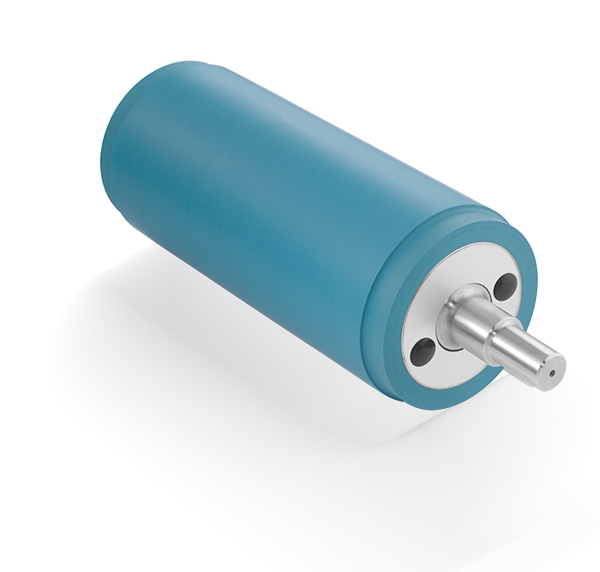

Rubber Coating, cross-/profile-grinding

Roll body ground by stone, rubber coated with various qualities such as EPDM, NBR, PUR, silicone, viton a.s.o., Roll surface ground by stone, optional cross-grinding or profile-grinding e.g. Ra = 0,4 µm, Ra = 0,8 µm

Copper

Roll body ground by stone, copper plated, thickness depending on requirements and application, finishmaster-treatment and/or polishmaster-treatment as preparation for engraving, gravure cylinder or surface finish

Hard-Coated (Hard-Eloxal) and matted

electrolytic oxidation of aluminum-sleeve(s) as a protection against abrasion and/or corrosion Roll body mechanically matted and hard-coated, e.g. Rt = 5-10 µm

Chrome, Mechanically Matted

Roll body ground by stone, surface blasted, e.g. Rt = 5-10 µm, flash chrome plated, approx. 30-50 µm thickness

Rubber Coating, shouldered ends

Roll body ground by stone and rubber coated special coating, otherwise rubber coated with various qualities such as EPDM, NBR, PUR, Silicone, Viton a.s.o., Roll surface ground by stone, optional cross-grinding or profile-grinding e.g. Ra = 0,4 µm, Ra = 0,8 µm

Engraving 1

Roll body ground by stone, engraved with various designs such as prism, chessboard, bubbles a.s.o., flash chrome plated, approx. 30-50 µm thickness

Nickel

Roll body ground by stone, galvanic or electroless nickel plated, ground by stone

Hard-Coated (Hard-Eloxal) and polished

electrolytic oxidation of aluminum-sleeve(s) as a protection against abrasion and/or corrosion Roll body either belt- or stone polished and hard-coated, Rt = 2-3 µm, thickness approx. 50 µm

Chrome, Electrolytically Matted

Roll body ground by stone, multi-layer chrome plated, electroplated matt and chrome plated, approx. 100-120 µm final thickness e.g. „silky matt“ Rt = 3-5 µm or „orange-peel“ Rt = 40-50 µm

Rubber Coating, incl. Teflon-sleeve

Roll body ground by stone and rubber coated with EPDM-quality, additionally manufactured with a shrink-fit Teflon-sleeve, total hardness approx. 85 Shore A, ground and polished, special non-sticky properties

Engraving 2

Roll body ground by stone, optional copper plated (approx. 1 mm) or nickel plated (approx. 100 µm), engraved with various designs such as leather, prism, hygienic, sand, skyto, chessboard, orange-peel, a.s.o., flash chrome plated, approx. 30-50 µm thickness technologies: depending on design either engraving (molettage), etching or laser-engraving.

Thermal Spraying

Technologies: plasma spraying, arc spraying, high-velocity-oxygen-fuel spraying (HVOF), detonation coating Roll body ground by stone, miscellaneous surfaces.

TungstenCarbide (WC-Co)

Special part of thermal spraying (see pos. 9 ) Roll body ground by stone, coated (sprayed) with bases-layer and additional Wofram-Carbide (WC) and Cobalt (WC-Co) approx. 100-250 µm final layer ground by stone, alternatively crowned, polished and finish polished e.g. Rt = 0,2 µm