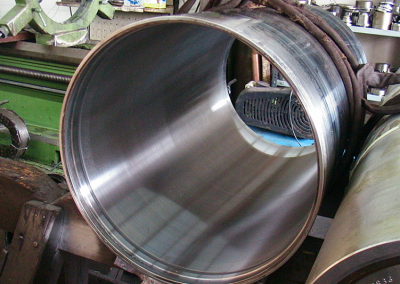

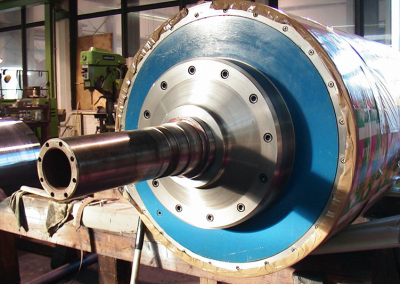

1- Changing of outer sleeve, due to: interior pollution of cooling channels | non-repairable damages | improved properties → hard face sleeve, improved cooling efficiency

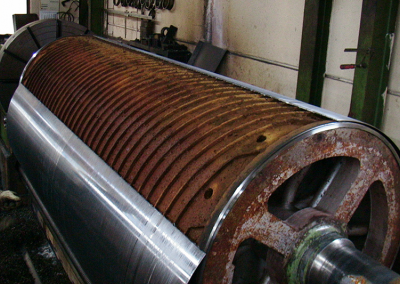

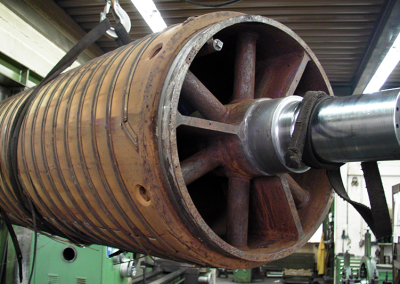

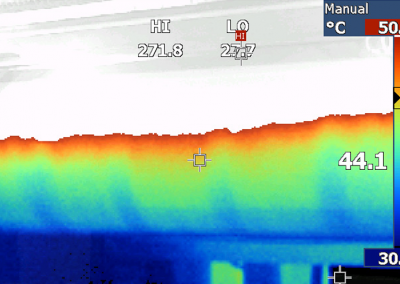

2- Dis-assembling and (mechanical) cleaning due to heavily pollution of interior cooling channels

3- Flushing (chemical cleaning) due to pollution of interior cooling channels

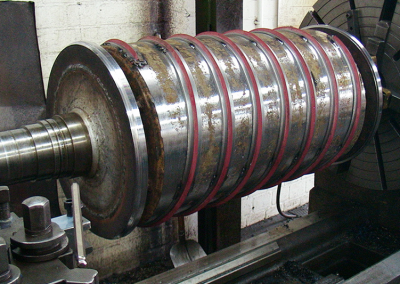

4- New coating due to abrasion, ozone, chlorides etc.

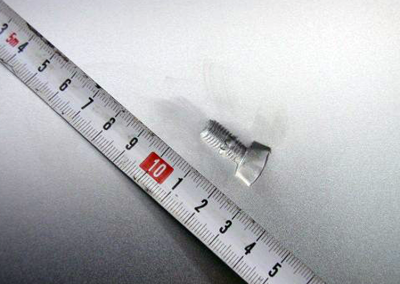

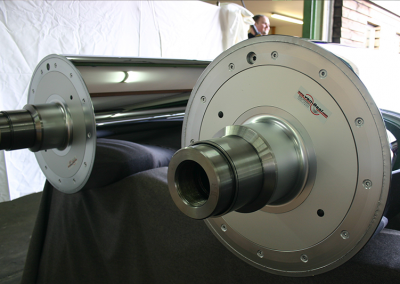

5- Journal repair / modification due to: damage | modification of the extrusion line (machine)

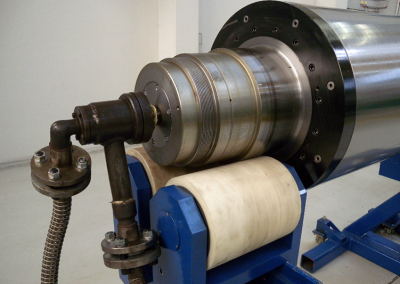

6- Change / modification of the bearings due to abrasion or change to new type or technology

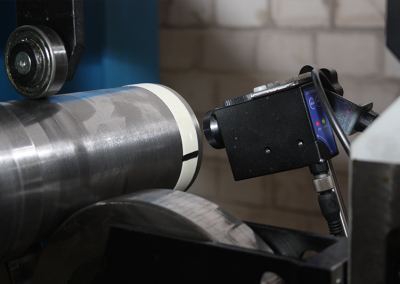

7- Dynamical balancing

8- Pick-up and return – service